The electrical system of the Massey Ferguson 3050 tractor is essential for powering critical components and ensuring efficient operation in agricultural settings. This blog post delves into essential maintenance practices to uphold electrical system reliability, covering inspection routines, troubleshooting techniques, component care, and the integration of modern technologies.

1. Importance of Electrical Systems Maintenance:

Effective maintenance enhances the longevity and performance of the Massey Ferguson 3050 electrical system:

-

System Integrity: Regular maintenance prevents electrical faults, ensuring consistent operation of lighting, instrumentation, and safety systems.

-

Component Longevity: Proper care extends the lifespan of crucial components such as batteries, alternators, and wiring harnesses.

-

Operational Efficiency: Well-maintained electrical systems minimize downtime, optimizing productivity during agricultural operations.

Understanding the significance of maintenance lays the foundation for dependable tractor performance.

2. Routine Inspection and Diagnostic Procedures:

Implement thorough inspection routines to detect potential issues early:

-

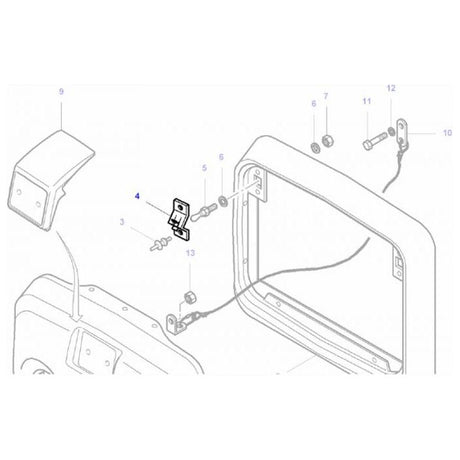

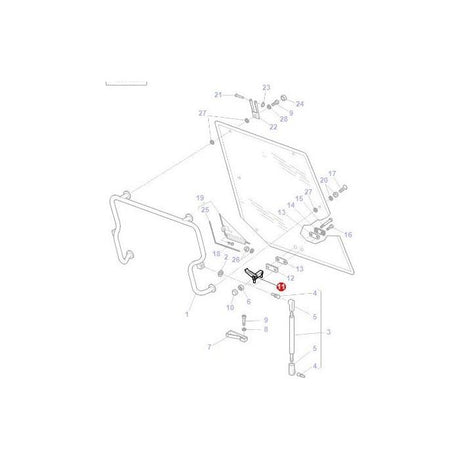

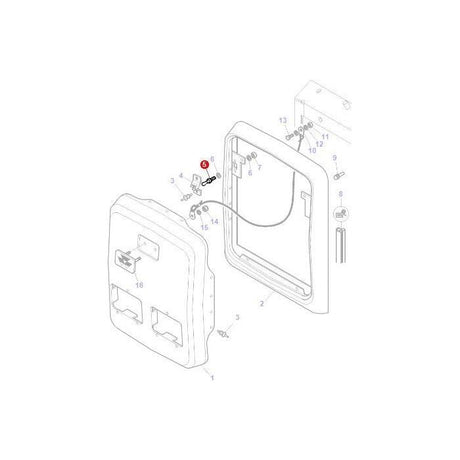

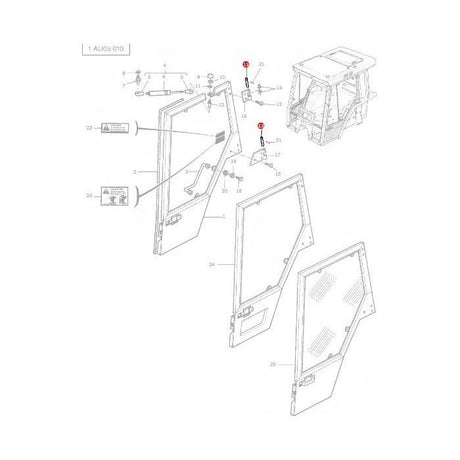

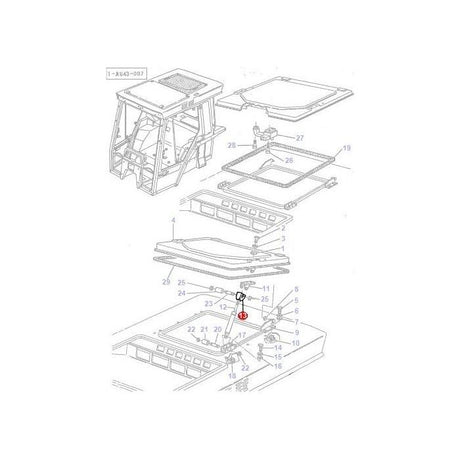

Visual Checks: Inspect wiring harnesses, connectors, and terminals for signs of wear, corrosion, or loose connections.

-

Battery Health: Test battery voltage regularly and clean terminals to prevent corrosion buildup, ensuring reliable starts.

-

Charging System: Monitor alternator output and rectify any voltage irregularities to sustain battery charge and electrical supply.

Proactive inspection mitigates risks of electrical system malfunctions and enhances reliability.

3. Troubleshooting Techniques for Electrical Issues:

Equip yourself with effective troubleshooting strategies:

-

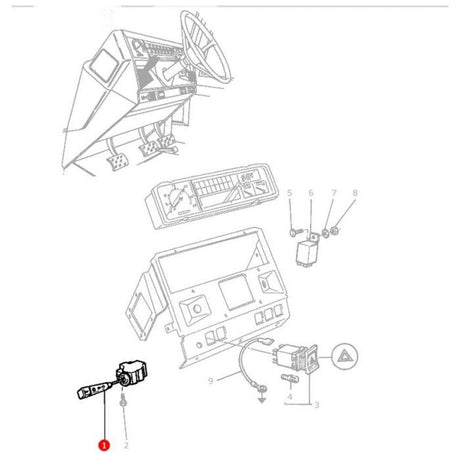

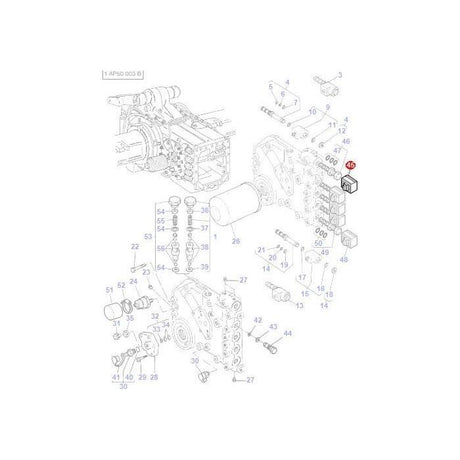

Fuse and Relay Examination: Check fuse boxes and relay panels for blown fuses or faulty relays, replacing as needed to restore electrical functions.

-

Voltage and Continuity Testing: Use multimeters to verify circuit continuity and voltage levels, pinpointing root causes of electrical failures.

-

Grounding Inspections: Inspect grounding points for corrosion or poor connections, rectifying issues to ensure effective circuit completion.

Proficient troubleshooting skills enable prompt resolution of electrical system issues and minimize operational disruptions.

4. Component-Specific Maintenance Practices:

Focus on maintenance tailored to key electrical components:

-

Starter Motor: Grease drive mechanisms and inspect solenoids for wear, ensuring reliable engine starting.

-

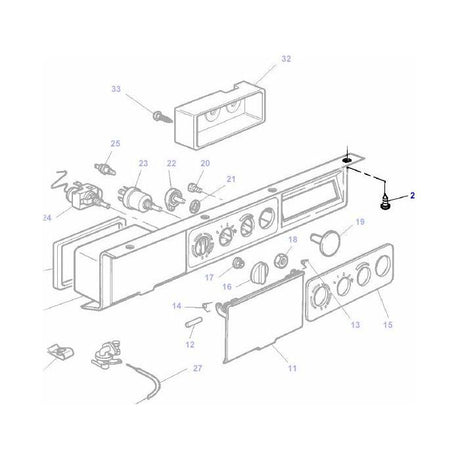

Lighting Systems: Clean lenses and replace bulbs promptly to maintain visibility and compliance with safety regulations.

-

Instrumentation Calibration: Calibrate dashboard instruments periodically to ensure accurate readings and operational insights.

Adhering to manufacturer guidelines enhances component performance and overall electrical system reliability.

5. Integration of Advanced Technologies:

Explore modern solutions for optimizing electrical system performance:

-

Electronic Control Units (ECUs): Utilize ECUs for real-time monitoring and adjustment of engine parameters and electrical functions.

-

Telematics Systems: Implement telematics for remote monitoring of electrical system health and predictive maintenance planning.

-

Precision Agriculture Tools: Integrate GPS and precision agriculture technologies to optimize electrical system settings for enhanced efficiency.

Harnessing advanced technologies enhances tractor performance, efficiency, and operational insights.

Maintaining the Massey Ferguson 3050 electrical system ensures reliability, efficiency, and longevity in agricultural operations. By adopting proactive maintenance practices, leveraging diagnostic techniques, and integrating advanced technologies, farmers can optimize their tractor's electrical system performance and minimize downtime.

Ready to enhance your Massey Ferguson 3050 tractor's electrical system maintenance? Explore Farmingparts.com for a comprehensive range of maintenance products, diagnostic tools, and expert support designed to maximize your tractor's reliability and productivity.