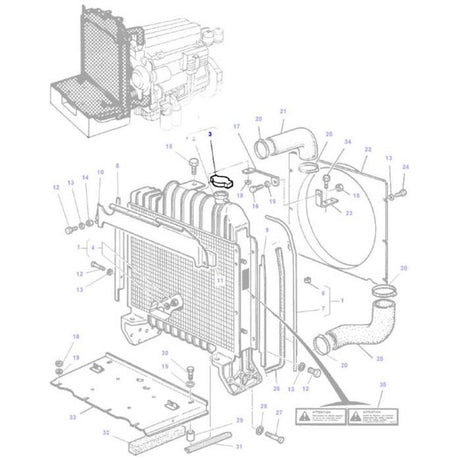

Hydraulic systems are the backbone of a Massey Ferguson 135 tractor's functionality, powering everything from lifting mechanisms to attachment controls. Among the key components of this system are the Massey Ferguson 135 Hydraulic Hoses and Fittings. Proper understanding and maintenance of these parts are essential for ensuring efficient and reliable operation. In this guide, we'll delve into the significance of hydraulic hoses and fittings, common issues, and tips for maintaining them.

1. Importance of Hydraulic Hoses and Fittings

A. Functionality in the Hydraulic System

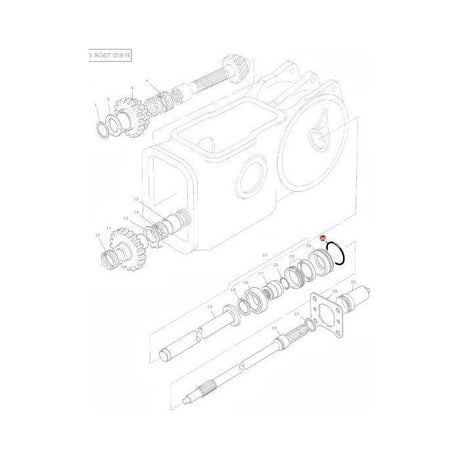

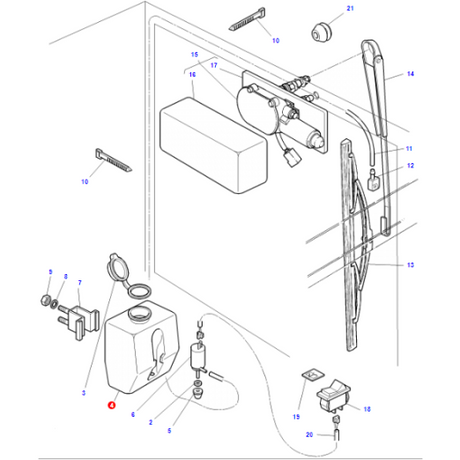

Hydraulic hoses and fittings are crucial for transporting hydraulic fluid throughout the system. They enable the transfer of power to various components and attachments.

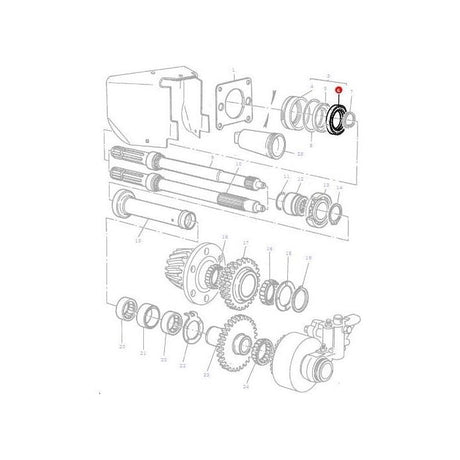

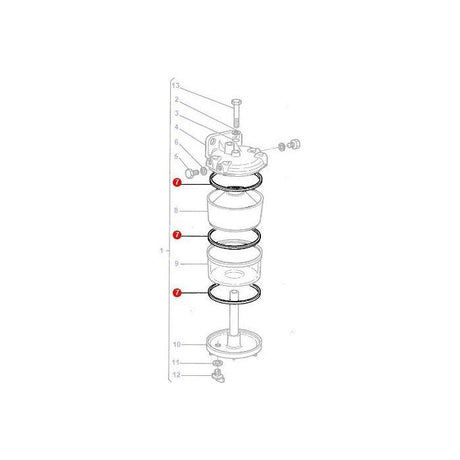

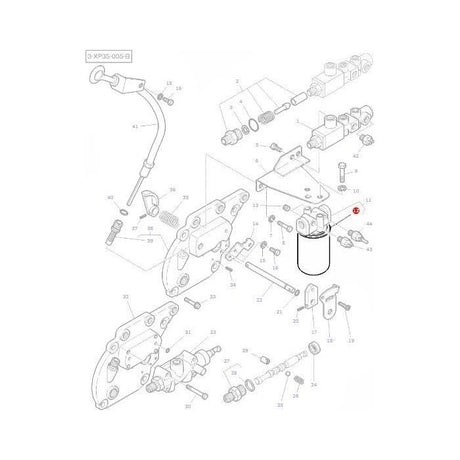

- Hydraulic Hoses: These flexible tubes carry hydraulic fluid from the pump to the cylinders and other components. They need to withstand high pressure and resist wear and tear.

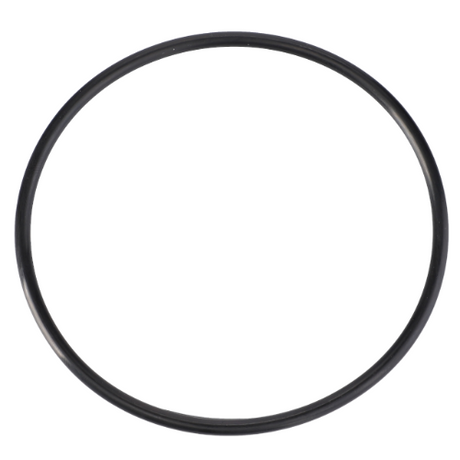

- Hydraulic Fittings: These are connectors that join hoses and other components. They ensure a secure, leak-proof connection within the hydraulic system.

B. Impact on Tractor Performance

- Efficiency: Properly functioning hydraulic hoses and fittings ensure that hydraulic fluid flows smoothly, optimizing the performance of the tractor.

- Safety: Well-maintained hoses and fittings prevent leaks and potential hazards, ensuring safe operation of the tractor.

2. Common Issues with Hydraulic Hoses and Fittings

A. Leaks

- Symptoms: Noticeable fluid leaks around the hoses or fittings.

- Causes: Cracks, abrasions, or loose connections. Over time, hoses can become brittle or worn out due to exposure to harsh conditions.

B. Blockages

- Symptoms: Reduced performance or unresponsive hydraulic components.

- Causes: Debris or contaminants blocking the flow of hydraulic fluid. Blockages can disrupt the normal operation of the hydraulic system.

C. Wear and Tear

- Symptoms: Visible signs of wear, such as fraying or bulging in the hoses.

- Causes: Continuous use, exposure to extreme temperatures, or physical damage.

3. Maintenance Tips for Hydraulic Hoses and Fittings

A. Regular Inspections

- Check for Leaks: Regularly inspect hydraulic hoses and fittings for signs of leaks or damage. Address any issues immediately to prevent system failure.

- Monitor Performance: Ensure that all hydraulic functions operate smoothly. Any unusual performance issues could indicate a problem with the hoses or fittings.

B. Cleaning and Replacement

- Clean Hoses: Regularly clean hydraulic hoses to remove dirt and debris that could cause blockages or damage.

- Replace Worn Parts: Replace any hoses or fittings that show signs of wear or damage. Using high-quality replacement parts ensures continued performance and reliability.

C. Proper Installation

- Secure Connections: Ensure that all hydraulic fittings are tightly secured to prevent leaks. Use the appropriate tools and techniques for installation.

- Avoid Kinks: Ensure that hoses are routed properly to avoid kinks or sharp bends, which can weaken the hoses and lead to failure.

4. Benefits of Using Quality Hydraulic Parts

A. Enhanced Performance

- Reliable Operation: High-quality hydraulic hoses and fittings ensure reliable and efficient operation of your Massey Ferguson 135.

- Optimal Power Transfer: Properly maintained and high-quality parts facilitate smooth power transfer throughout the hydraulic system.

B. Increased Safety

- Leak Prevention: Quality components reduce the risk of leaks and potential safety hazards.

- Reduced Downtime: Regular maintenance and using quality parts minimize the risk of unexpected failures and downtime.

C. Cost Efficiency

- Long-Term Savings: Investing in quality hydraulic hoses and fittings and maintaining them properly can save you money in the long run by reducing the need for frequent replacements and repairs.

5. Where to Buy Massey Ferguson 135 Hydraulic Hoses and Fittings

For top-quality Massey Ferguson 135 Hydraulic Hoses and Fittings, visit our collection. We offer a comprehensive range of parts to keep your hydraulic system in optimal condition.

Understanding and maintaining your Massey Ferguson 135 hydraulic hoses and fittings is vital for ensuring the efficient operation of your tractor. Regular inspections, proper maintenance, and using high-quality replacement parts can enhance performance, improve safety, and reduce long-term costs. Explore our Massey Ferguson 135 Hydraulic Hoses and Fittings collection to find the parts you need for effective maintenance and repairs.

Ensure your Massey Ferguson 135 operates at peak performance with top-quality hydraulic parts. Browse our Massey Ferguson 135 Hydraulic Hoses and Fittings collection today and keep your tractor's hydraulic system running smoothly.