Understanding the hydraulic system of the Massey Ferguson 3050 is crucial for optimizing tractor performance and efficiency in agricultural operations. This blog post provides an in-depth exploration of hydraulic systems, covering components, functions, maintenance requirements, troubleshooting tips, and strategies to enhance tractor productivity.

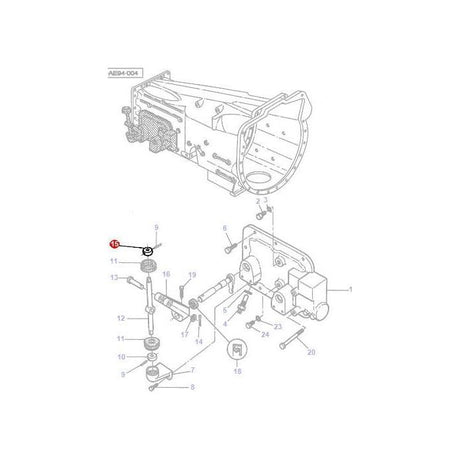

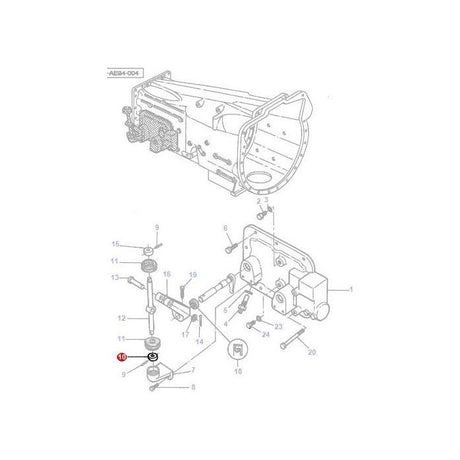

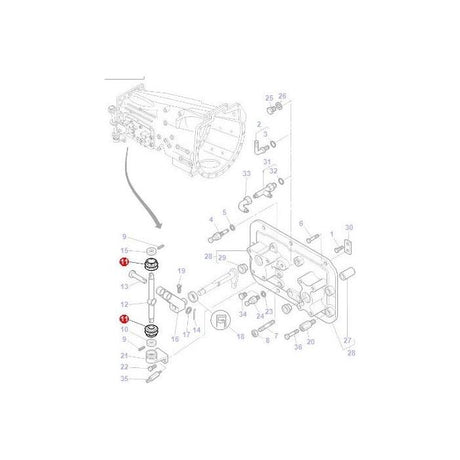

1. Components of the Hydraulic System:

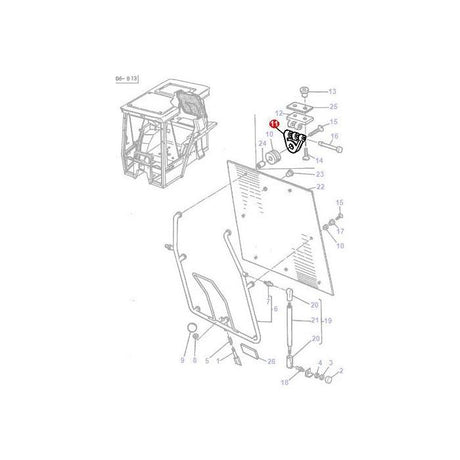

The Massey Ferguson 3050 hydraulic system comprises essential components that work together to power implements, adjust lifting mechanisms, and control auxiliary functions:

-

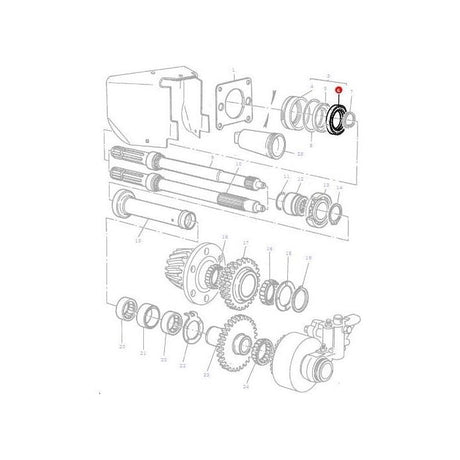

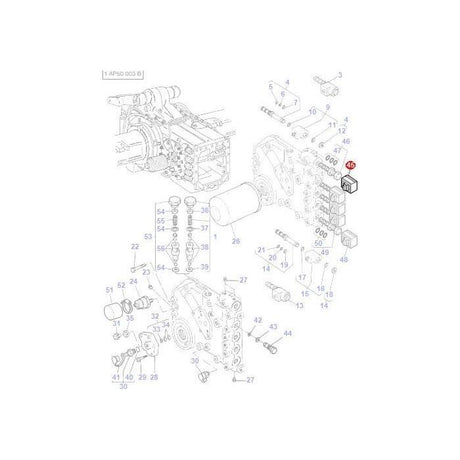

Hydraulic Pump: The heart of the system that pressurizes hydraulic fluid for power transmission.

-

Hydraulic Fluid: Transfers power and lubricates components within the system, ensuring smooth operation and heat dissipation.

-

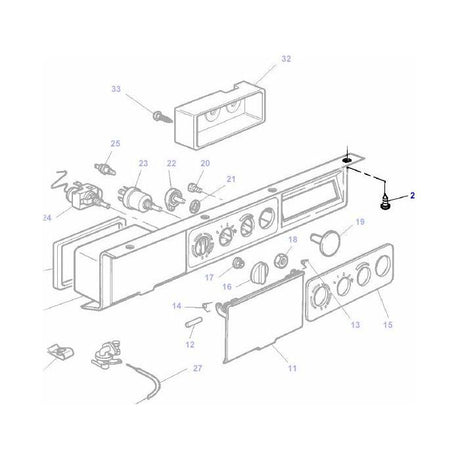

Control Valves: Direct flow and pressure to specific hydraulic circuits, allowing operators to control implement functions.

-

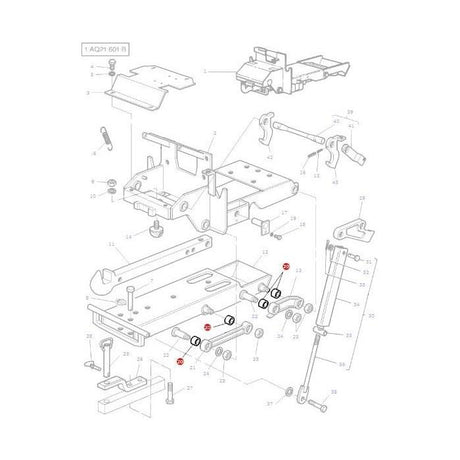

Cylinders: Convert hydraulic pressure into mechanical force to operate lift arms or other attachments.

-

Filters and Reservoir: Maintain fluid cleanliness and ensure adequate supply for consistent system performance.

Understanding these components and their roles is essential for effective hydraulic system operation and maintenance.

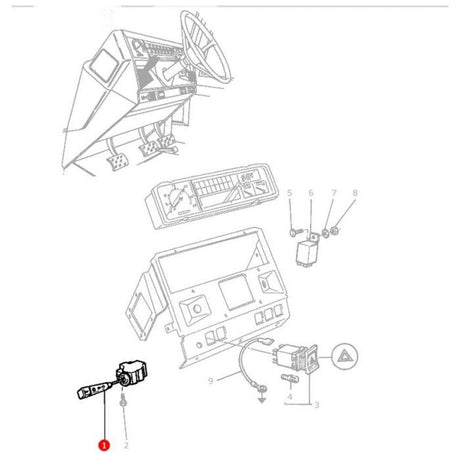

2. Hydraulic System Functions and Applications:

Explore the versatile applications and functions of the Massey Ferguson 3050 hydraulic system:

-

Lift Capacity: Powering the tractor's three-point hitch to lift and lower implements, adjusting depth and leveling for optimal soil engagement.

-

Auxiliary Connections: Providing hydraulic power to front-end loaders, hydraulic motors, or other attachments for increased versatility and productivity.

-

Remote Hydraulics: Facilitating simultaneous operation of multiple hydraulic functions, enhancing operational efficiency in complex tasks.

-

Steering Assist: Some models utilize hydraulic power steering, ensuring responsive and precise steering control in various field conditions.

Understanding these functions enables operators to leverage hydraulic power effectively, maximizing tractor utility and operational efficiency.

3. Maintenance and Fluid Management:

Implementing regular maintenance practices is critical for preserving hydraulic system performance and reliability:

-

Fluid Checks and Changes: Regularly inspect hydraulic fluid levels and quality, ensuring proper lubrication and heat dissipation. Change fluid at recommended intervals to prevent contamination and maintain optimal viscosity.

-

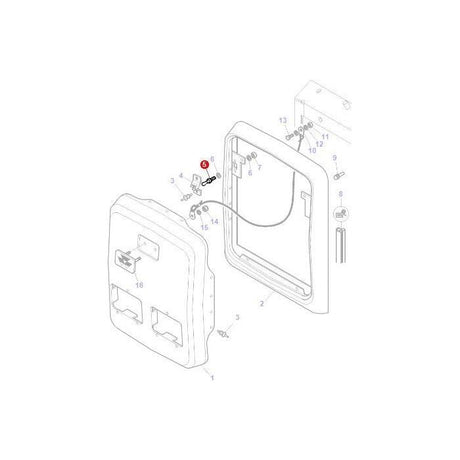

Filter Replacements: Replace hydraulic filters as per manufacturer guidelines to remove contaminants and maintain clean fluid circulation.

-

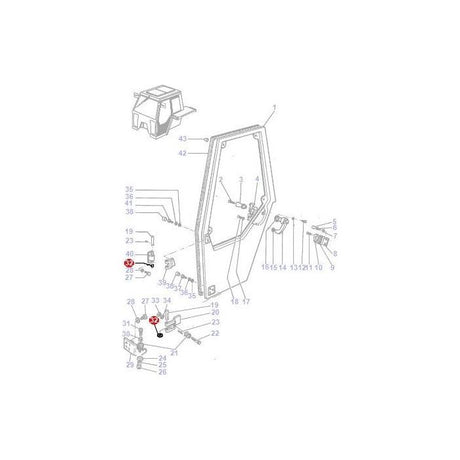

Seal Inspections: Check hydraulic seals for leaks or wear, ensuring efficient fluid containment and preventing system inefficiencies.

-

Pressure and Flow Tests: Periodically perform pressure and flow tests to verify hydraulic system performance and detect potential issues early.

By prioritizing maintenance and using quality hydraulic fluids and parts, operators can minimize downtime and costly repairs while maximizing system longevity.

4. Troubleshooting Hydraulic Issues:

Equip yourself with troubleshooting skills to identify and address common hydraulic problems promptly:

-

Loss of Hydraulic Power: Diagnose causes such as low fluid levels, pump failure, or clogged filters. Addressing these issues restores hydraulic power and system functionality.

-

Slow or Erratic Movements: Investigate potential causes like air in the system, valve malfunctions, or worn components. Bleeding air or replacing faulty parts resolves these issues.

-

Fluid Leaks: Inspect hydraulic lines, fittings, and seals for leaks. Prompt repairs prevent fluid loss and potential damage to components.

Understanding these troubleshooting techniques enables proactive maintenance and ensures uninterrupted hydraulic system operation.

5. Enhancing Efficiency and Performance:

Explore strategies to optimize Massey Ferguson 3050 hydraulic system efficiency and performance:

-

Proper Fluid Selection: Choose hydraulic fluids recommended by Massey Ferguson for optimal viscosity, lubrication, and compatibility with system components.

-

Regular Inspections: Conduct routine inspections to detect and address potential issues before they escalate, ensuring reliable system operation.

-

Operator Training: Provide training on hydraulic system operation and maintenance practices to enhance operator proficiency and system longevity.

Implementing these strategies promotes efficient hydraulic system operation, enhances tractor productivity, and reduces operational costs in agricultural settings.

Mastering the Massey Ferguson 3050 hydraulic system through comprehensive understanding, regular maintenance, and effective troubleshooting is essential for maximizing tractor performance and reliability. By prioritizing hydraulic system care and accessing quality parts at Farmingparts.com, farmers can ensure their tractors operate efficiently and effectively in various agricultural tasks.

Ready to optimize your Massey Ferguson 3050 hydraulic system? Visit Farmingparts.com today to explore our selection of hydraulic components, fluids, filters, and maintenance products designed to enhance your tractor's reliability and productivity.