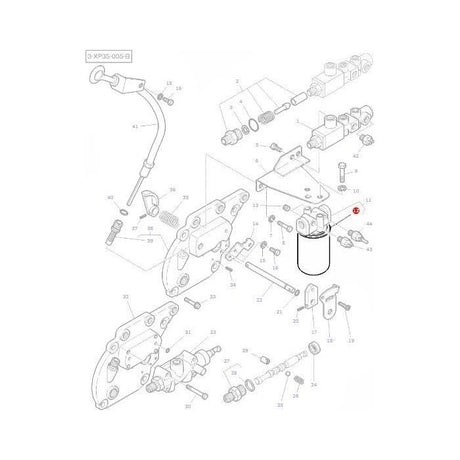

Hydraulic valves are critical components in the hydraulic system of a Massey Ferguson 135 tractor. They control the flow and direction of hydraulic fluid, ensuring that the tractor's attachments and mechanisms operate smoothly and efficiently. In this guide, we’ll explore everything you need to know about Massey Ferguson 135 Hydraulic Valves, including their functions, common issues, maintenance tips, and where to find high-quality replacement parts.

1. Understanding Massey Ferguson 135 Hydraulic Valves

A. Role of Hydraulic Valves

Hydraulic valves play a pivotal role in managing the hydraulic fluid within the system. They control:

- Fluid Flow: Regulate the amount of hydraulic fluid flowing to various components.

- Direction: Direct the flow of fluid to the appropriate part of the system.

- Pressure: Maintain and regulate hydraulic pressure for optimal performance.

B. Types of Hydraulic Valves

- Directional Control Valves: Direct the hydraulic fluid to different parts of the system, allowing for versatile functionality.

- Pressure Relief Valves: Prevent over-pressurization by releasing excess fluid, protecting the system from damage.

- Flow Control Valves: Regulate the speed of hydraulic actuators by controlling the flow rate of the hydraulic fluid.

2. Common Issues with Hydraulic Valves

A. Leaks

- Symptoms: Noticeable fluid leakage around the valve.

- Causes: Worn seals, loose connections, or damaged valve bodies. Leaks can lead to decreased efficiency and potential damage to other components.

B. Sticking or Jamming

- Symptoms: Difficulty in operating the valve or unresponsive hydraulic functions.

- Causes: Contaminants, debris, or internal wear can cause valves to stick or jam, affecting performance.

C. Pressure Fluctuations

- Symptoms: Inconsistent or unstable hydraulic pressure.

- Causes: Faulty pressure relief valves or clogged filters can cause pressure fluctuations, impacting the tractor's overall functionality.

3. Maintenance Tips for Hydraulic Valves

A. Regular Inspections

- Check for Leaks: Regularly inspect hydraulic valves for signs of leaks. Addressing leaks promptly helps maintain system efficiency.

- Monitor Performance: Ensure smooth operation of hydraulic functions. Unusual behavior may indicate valve issues.

B. Cleaning and Replacement

- Clean Valves: Periodically clean hydraulic valves to remove debris and contaminants. This helps in maintaining smooth operation.

- Replace Worn Parts: Replace any damaged or worn valves to ensure continued reliable performance. Using high-quality replacement parts is essential.

C. Proper Adjustment and Calibration

- Adjust Pressure Settings: Ensure that pressure relief valves are properly adjusted to maintain optimal hydraulic pressure.

- Calibrate Flow Control: Properly calibrate flow control valves to achieve desired actuator speeds and prevent operational issues.

4. Benefits of Using Quality Hydraulic Valves

A. Improved Performance

- Efficient Operation: High-quality hydraulic valves ensure that the hydraulic system operates efficiently, maximizing the performance of your Massey Ferguson 135.

- Reliable Functionality: Properly maintained valves provide reliable operation, reducing the risk of unexpected failures.

B. Enhanced Safety

- Leak Prevention: Quality valves reduce the risk of leaks, ensuring safe operation and preventing potential hazards.

- Consistent Pressure: Properly functioning valves maintain consistent hydraulic pressure, enhancing the safety and reliability of the tractor.

C. Long-Term Cost Savings

- Reduced Maintenance Costs: Investing in quality hydraulic valves and performing regular maintenance can reduce the need for frequent repairs and replacements.

- Extended Component Lifespan: High-quality valves and proper maintenance extend the lifespan of your hydraulic system, providing long-term savings.

5. Where to Find Massey Ferguson 135 Hydraulic Valves

For top-quality Massey Ferguson 135 Hydraulic Valves, visit our collection. We offer a comprehensive range of hydraulic valves designed to keep your tractor's hydraulic system in optimal condition.

Understanding and maintaining your Massey Ferguson 135 hydraulic valves is crucial for ensuring the efficient operation of your tractor. Regular inspections, proper maintenance, and using high-quality replacement parts can enhance performance, improve safety, and reduce long-term costs. Explore our Massey Ferguson 135 Hydraulic Valves collection to find the parts you need for effective maintenance and repairs.

Keep your Massey Ferguson 135 running smoothly with top-quality hydraulic valves. Browse our Massey Ferguson 135 Hydraulic Valves collection today to find the perfect parts for your tractor’s hydraulic system.