Synchronizers play a crucial role in the transmission system of your Massey Ferguson 390 tractor. These essential components ensure smooth and efficient gear shifting, making your tractor’s operation more reliable and less labor-intensive. In this comprehensive guide, we’ll delve into the function of synchronizers, common issues that may arise, and best practices for maintenance and replacement. Whether you're experiencing shifting problems or simply looking to understand how synchronizers work, this post provides all the information you need.

1. What Are Synchronizers in the Massey Ferguson 390?

A. Function of Synchronizers:

-

Smooth Gear Shifting: Synchronizers help in matching the speeds of the gears being engaged, allowing for smooth and seamless gear changes without grinding or jolting.

-

Prevent Gear Clash: By synchronizing the rotational speeds of gears, synchronizers prevent the clash or grind that can occur when gears are shifted at different speeds.

-

Enhance Transmission Life: Properly functioning synchronizers contribute to the longevity of the transmission system by reducing wear and tear on gear teeth.

B. Key Components of Synchronizers:

-

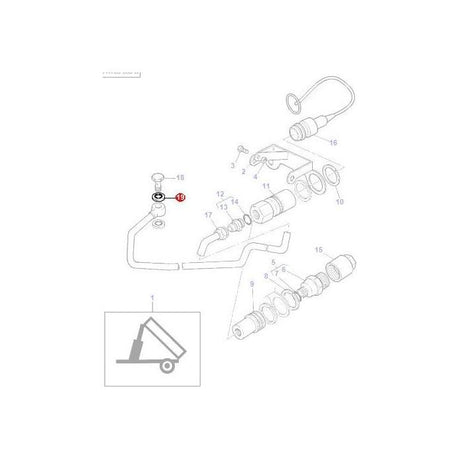

Synchronizer Ring: This component engages with the gear and the hub to synchronize their speeds. It typically features a cone-shaped design that facilitates smooth engagement.

-

Blocking Ring: Also known as the synchronizer blocking ring, it helps to lock the gear into place once synchronization is achieved.

-

Hub: The hub connects the synchronizer ring to the gear and enables the gear to slide into position.

-

Forks: Gearshift forks move the synchronizer and gear into the desired position during shifting.

2. Common Issues with Synchronizers

A. Difficulty Shifting Gears:

-

Symptoms: Hard or difficult gear changes, or the need to forcefully engage the gear.

-

Causes: Issues with synchronizers can arise from worn synchronizer rings, damaged blocking rings, or improper adjustment of the gearshift forks.

B. Gear Grinding:

-

Symptoms: Grinding noises when shifting gears, especially under load or during acceleration.

-

Causes: Gear grinding can occur due to worn or damaged synchronizers, misalignment, or faulty gear engagement.

C. Incomplete Engagement:

-

Symptoms: Gears that do not fully engage or pop out of gear during operation.

-

Causes: Problems with synchronizers may result from damaged rings, inadequate lubrication, or worn components.

D. Clashing Gears:

-

Symptoms: Hearing clashing or banging noises when changing gears.

-

Causes: Gear clashing often results from synchronization issues, where the gears are not matching speeds correctly.

3. Maintenance and Replacement Tips

A. Regular Inspections:

-

Frequency: Inspect the synchronizers as part of routine transmission maintenance. Look for signs of wear or damage, and listen for unusual noises during operation.

-

Method: Check the condition of the synchronizer rings and blocking rings. Ensure that the gearshift forks are correctly adjusted and that there is no excessive play or wear.

B. Lubrication:

-

Importance: Proper lubrication is essential for the smooth operation of synchronizers and the entire transmission system.

-

Schedule: Follow the manufacturer’s recommendations for lubricant types and change intervals. Regularly check and maintain the transmission fluid levels.

C. Addressing Issues Promptly:

-

Early Detection: Identify and address any signs of synchronizer issues early to prevent further damage and avoid costly repairs.

-

Replacement: Replace worn or damaged synchronizers with high-quality OEM or aftermarket parts to restore proper function.

D. Professional Servicing:

-

Quality Parts: Use genuine OEM or high-quality replacement synchronizers to ensure compatibility and reliable performance.

-

Expert Installation: Have synchronizers replaced or serviced by a qualified mechanic to ensure accurate installation and alignment.

4. Where to Find Quality Synchronizer Parts

A. Farmingparts.com

-

Extensive Selection: Browse our range of high-quality synchronizers and related parts for the Massey Ferguson 390 at Farmingparts.com. We offer both OEM and aftermarket options to suit your needs.

-

Expert Advice: Get professional guidance on selecting the right synchronizers and receive support for installation and maintenance.

-

Convenient Ordering: Enjoy easy online ordering with fast shipping options to get your parts quickly and efficiently.

Synchronizers are vital for smooth and efficient gear shifting in your Massey Ferguson 390 tractor. Understanding their function, recognizing common issues, and following proper maintenance and replacement practices will help ensure optimal transmission performance. For top-quality synchronizers and expert support, visit Farmingparts.com and find everything you need to keep your tractor running smoothly.

Ready to replace or upgrade your Massey Ferguson 390 synchronizers? Visit Farmingparts.com today to explore our selection of genuine OEM and high-quality parts. Get expert advice and ensure your tractor performs at its best with the right components.