For tractor enthusiasts and professionals alike, the Massey Ferguson 135 Synchronizers play a crucial role in ensuring smooth gear transitions and efficient tractor operation. This guide will provide an in-depth look at what synchronizers are, their importance in the Massey Ferguson 135, common issues, and tips for maintenance and replacement.

1. What Are Massey Ferguson 135 Synchronizers?

A. Definition and Function

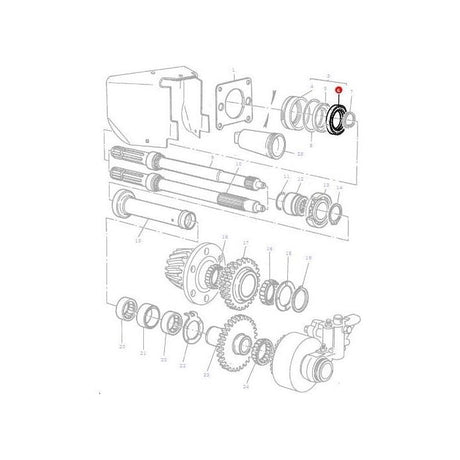

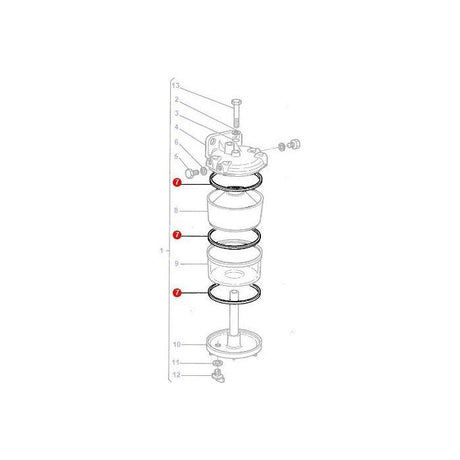

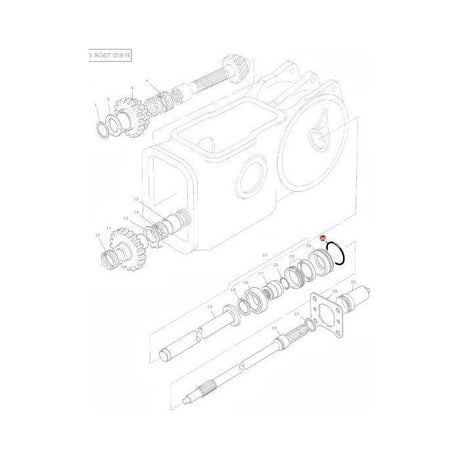

Massey Ferguson 135 Synchronizers are components within the tractor’s transmission system that facilitate smooth gear shifts. They ensure that the gears align correctly and engage without grinding or excessive force.

- Primary Function: Allow for smooth and efficient gear changes.

- Components: Typically include synchronizer rings, sleeves, and cones.

B. Importance in Tractor Operation

- Smooth Gear Engagement: Synchronizers help in achieving seamless gear changes, which is essential for maintaining operational efficiency and reducing wear on the transmission system.

- Reduced Gear Grinding: They minimize gear clash, which can lead to premature wear and damage.

2. Common Issues with Massey Ferguson 135 Synchronizers

A. Hard Shifting or Gear Grinding

- Symptoms: Difficulty in shifting gears, noticeable grinding noises.

- Causes: Worn synchronizer rings, misalignment, or contamination within the transmission.

- Solution: Inspect and replace worn synchronizer components, and ensure proper alignment.

B. Slipping Gears

- Symptoms: Gears slipping out of engagement, unexpected changes in gear position.

- Causes: Faulty synchronizers or worn gear teeth.

- Solution: Check and replace faulty synchronizers and examine gears for wear.

C. Sticking Gears

- Symptoms: Gears not moving smoothly, sticking or resistance when shifting.

- Causes: Accumulated dirt or debris, worn synchronizer rings.

- Solution: Clean the transmission and replace worn synchronizer rings.

3. Maintenance Tips for Massey Ferguson 135 Synchronizers

A. Regular Inspections

- Visual Checks: Periodically inspect the synchronizer components for signs of wear or damage.

- Operational Checks: Test the gear shifting for smoothness and functionality.

B. Proper Lubrication

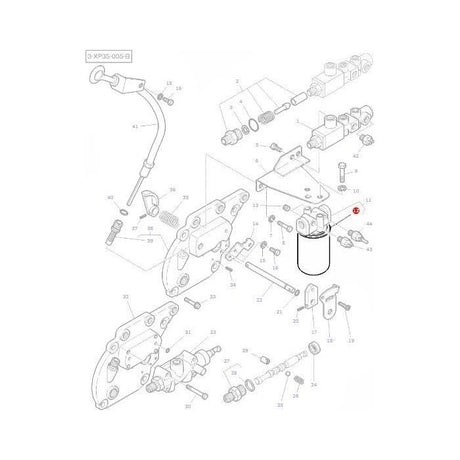

- Transmission Fluid: Use the recommended type and quantity of transmission fluid to ensure proper lubrication of synchronizers.

- Regular Changes: Change the transmission fluid as per the manufacturer's recommendations to prevent contamination.

C. Timely Replacements

- Worn Parts: Replace synchronizer rings, sleeves, and other components as needed to maintain optimal performance.

- High-Quality Parts: Use quality Massey Ferguson 135 Synchronizers to ensure durability and reliability.

4. Benefits of Using High-Quality Massey Ferguson 135 Synchronizers

A. Enhanced Performance

- Smooth Operation: High-quality synchronizers ensure smooth gear transitions, which enhances the overall performance of the tractor.

- Reliable Shifting: Reduces the likelihood of gear grinding and slipping, providing a more enjoyable and efficient driving experience.

B. Increased Longevity

- Durable Construction: High-quality parts are designed to last longer and withstand the rigors of heavy-duty use.

- Cost Efficiency: Investing in quality synchronizers reduces the frequency of replacements and repairs.

C. Improved Tractor Handling

- Better Control: Smooth and reliable gear changes contribute to improved control and handling of the tractor, especially in demanding agricultural tasks.

- Reduced Wear: Properly functioning synchronizers minimize wear on the transmission system, extending the life of your tractor.

5. Where to Find Massey Ferguson 135 Synchronizers

For reliable and high-quality Massey Ferguson 135 Synchronizers, visit our dedicated collection. We offer a range of synchronizer components designed to keep your tractor’s transmission system running smoothly.

Understanding and maintaining your Massey Ferguson 135 synchronizers is key to ensuring smooth and efficient tractor operation. Regular inspections, proper lubrication, and timely replacements of synchronizer components will keep your tractor performing at its best. Explore our Massey Ferguson 135 Parts Collection for the highest quality synchronizers and other essential parts.

Optimize your Massey Ferguson 135’s performance with top-notch synchronizer parts. Browse our Massey Ferguson 135 Synchronizers collection today and keep your tractor in peak condition.