Understanding the transmission system of the Massey Ferguson 3050 is essential for optimizing tractor performance and efficiency in agricultural operations. This blog post delves into the intricacies of the transmission, covering its components, operation, maintenance requirements, troubleshooting tips, and strategies to enhance overall tractor productivity.

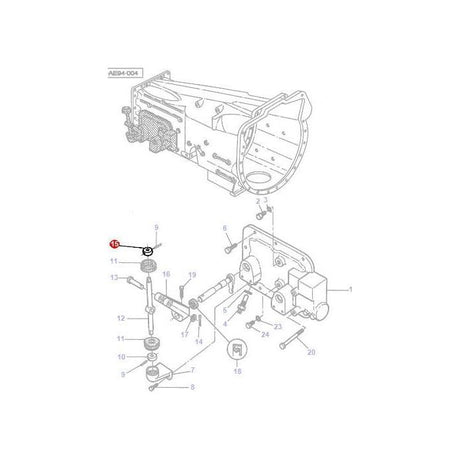

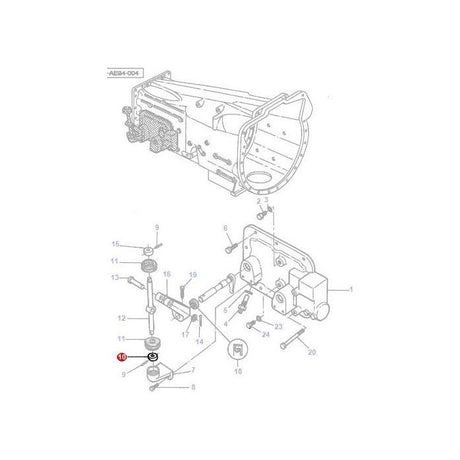

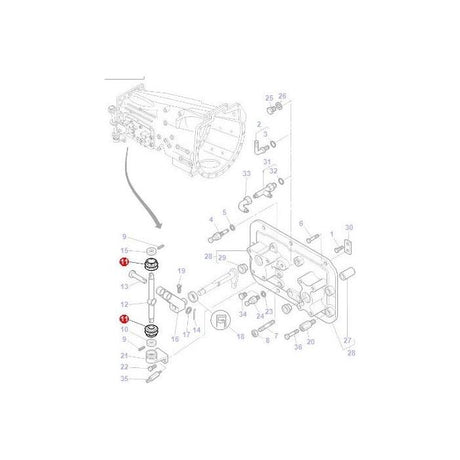

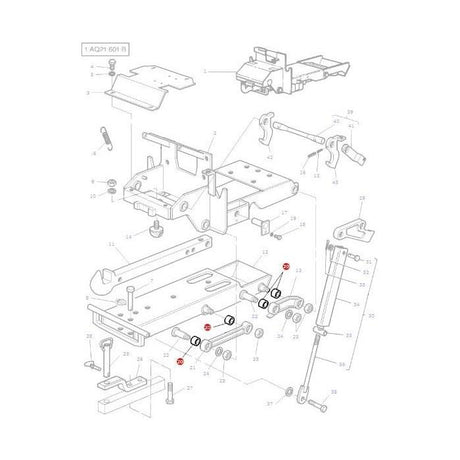

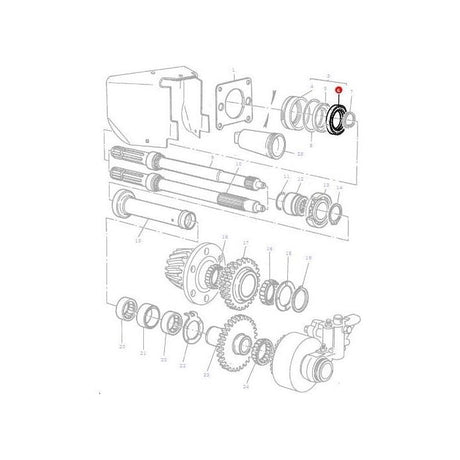

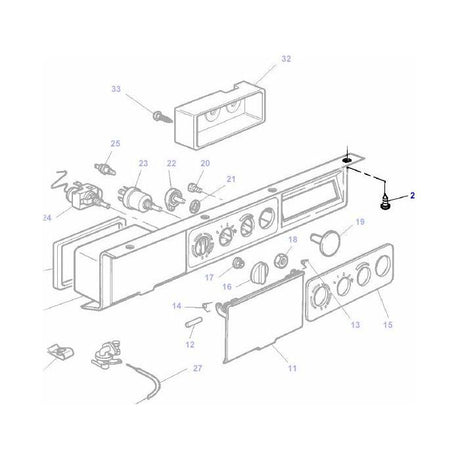

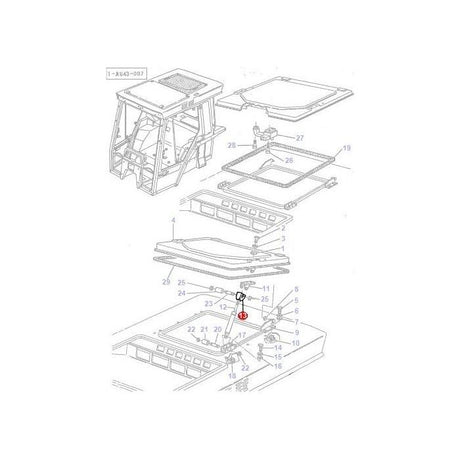

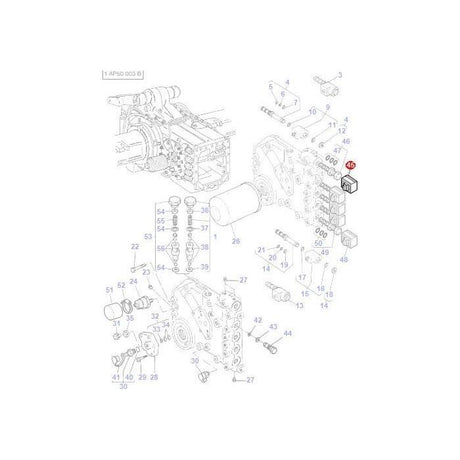

1. Components of the Transmission System: The Massey Ferguson 3050 transmission system consists of several key components that work together to transfer power from the engine to the wheels effectively. These components include the gearbox, clutch assembly, differential, gears, shifters, and hydraulics. Each component plays a crucial role in controlling speed, torque, and direction, adapting to varying terrain and operational needs on the farm.

Understanding the function and interaction of these components is essential for optimizing gear selection, improving fuel efficiency, and maximizing traction in different field conditions.

2. Types of Transmission Systems: Explore different types of transmission systems used in the Massey Ferguson 3050, such as manual transmission and hydrostatic transmission. Understand the advantages of each type in terms of efficiency, ease of operation, and suitability for specific agricultural tasks.

-

Manual Transmission: Provides precise control over gear selection and is preferred for tasks requiring varying speeds and torque.

-

Hydrostatic Transmission: Offers smooth acceleration and deceleration without the need for clutching or shifting, ideal for tasks requiring constant speed adjustments.

Choosing the right transmission type based on operational requirements can significantly enhance tractor performance and operator comfort.

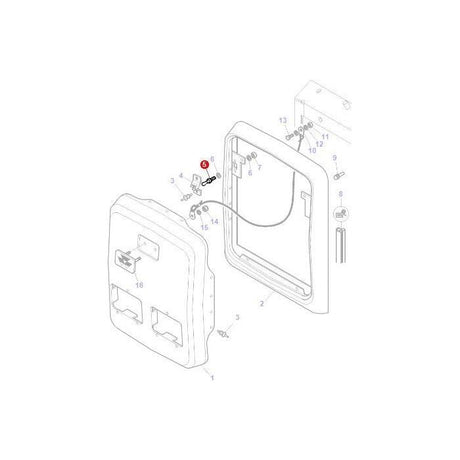

3. Maintenance Requirements: Implementing regular maintenance practices is crucial for ensuring the longevity and reliability of the Massey Ferguson 3050 transmission system.

-

Fluid Checks and Changes: Regularly inspecting transmission fluid levels and quality helps maintain proper lubrication and cooling, preventing premature wear and overheating.

-

Filter Replacements: Changing transmission filters at recommended intervals ensures clean fluid circulation, reducing the risk of debris accumulation and component damage.

-

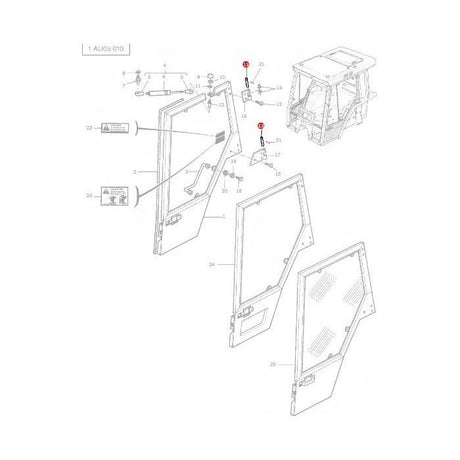

Clutch Adjustments: Periodic adjustments to clutch settings ensure smooth engagement and disengagement, optimizing power transfer and minimizing wear on clutch components.

-

Gearbox Inspections: Checking gearbox components for leaks, wear, or abnormal noise indicates potential issues that require immediate attention to prevent costly repairs.

Adhering to manufacturer-recommended maintenance schedules and using quality transmission fluids and parts are critical for maintaining optimal transmission performance.

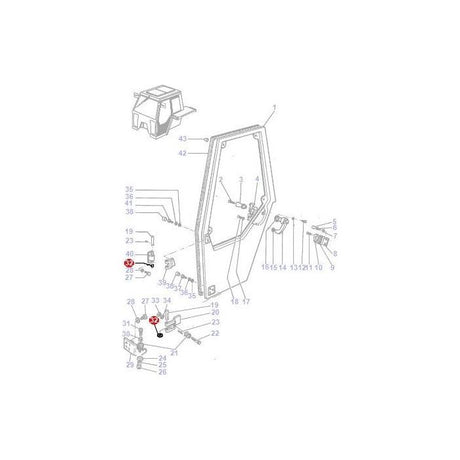

4. Troubleshooting Common Issues: Equip yourself with troubleshooting skills to identify and address common transmission problems promptly.

-

Slipping Gears: Diagnose causes of gear slippage, such as low fluid levels or worn clutch discs, and take corrective actions to restore transmission performance.

-

Noise or Vibration: Investigate sources of abnormal noise or vibration during operation, such as worn bearings or misaligned components, and perform necessary repairs.

-

Difficulty Shifting: Address issues related to difficult or delayed gear shifts by inspecting shift linkages, hydraulic systems, or clutch adjustments.

Understanding common transmission issues and their root causes allows for timely intervention, minimizing downtime and ensuring uninterrupted tractor operation.

5. Enhancing Efficiency and Performance: Explore strategies for optimizing transmission efficiency and performance to meet the demands of modern agricultural practices.

-

Gear Selection Techniques: Learn about optimal gear selection for different tasks to maximize fuel efficiency and reduce engine strain.

-

Operator Training: Provide training on proper transmission operation and maintenance practices to enhance operator efficiency and prolong transmission lifespan.

-

Technology Integration: Consider advancements in transmission technology, such as electronic controls or automated shifting systems, to improve tractor productivity and operational precision.

Implementing these strategies enhances overall tractor efficiency, reduces operating costs, and supports sustainable agricultural practices.

Mastering the Massey Ferguson 3050 transmission system through comprehensive understanding, regular maintenance, and effective troubleshooting is essential for maximizing tractor performance and durability. By prioritizing transmission care and accessing quality parts at Farmingparts.com, farmers can ensure their tractors operate reliably and efficiently in various field conditions.

Ready to optimize your Massey Ferguson 3050 transmission system? Visit Farmingparts.com today to explore our selection of transmission components, maintenance products, and accessories designed to enhance your agricultural productivity.