Proper maintenance of the hydraulic system is crucial for the Massey Ferguson 3050 tractor's reliability and performance in agricultural operations. This blog post provides essential maintenance tips, including fluid management, inspection techniques, troubleshooting advice, and proactive measures to maximize hydraulic system longevity and efficiency.

1. Regular Fluid Checks and Maintenance:

Hydraulic fluid is the lifeblood of the Massey Ferguson 3050 hydraulic system:

-

Fluid Quality: Monitor fluid levels and condition regularly. Top up or change fluids as per manufacturer recommendations to maintain optimal viscosity and performance.

-

Fluid Type: Use recommended hydraulic fluids suitable for agricultural applications. Ensure compatibility with system components to prevent damage and ensure efficient operation.

-

Filter Maintenance: Replace hydraulic filters at recommended intervals to prevent contamination and maintain fluid cleanliness. Clean or replace breathers to minimize moisture and debris ingress.

Proper fluid management is essential for preserving hydraulic system integrity and performance.

2. Inspection and Component Care:

Regular inspections help identify potential issues before they escalate:

-

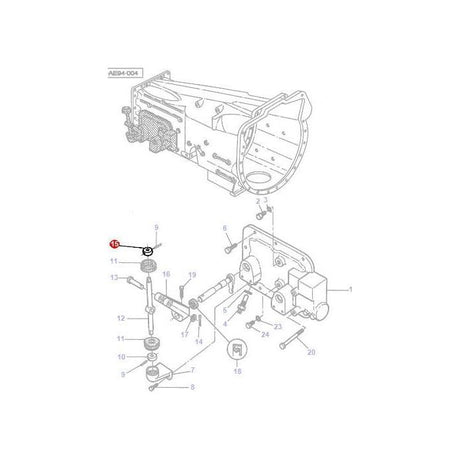

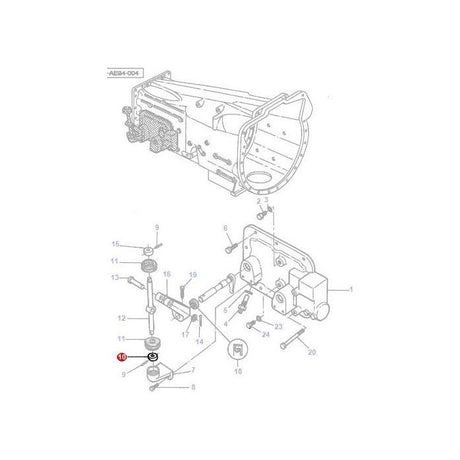

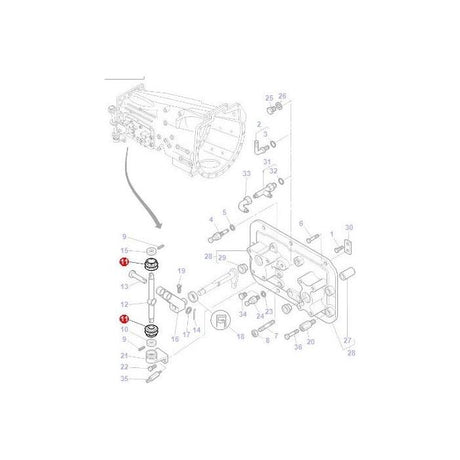

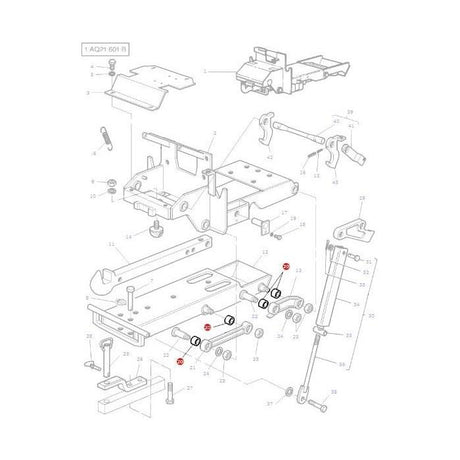

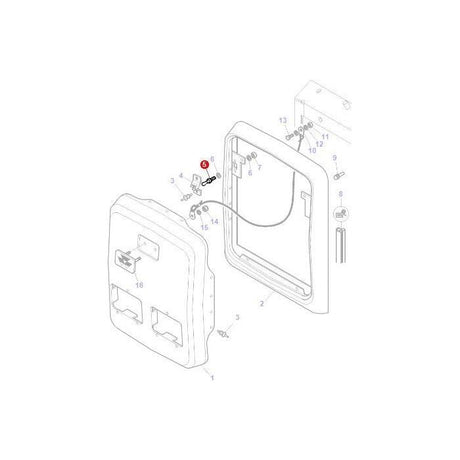

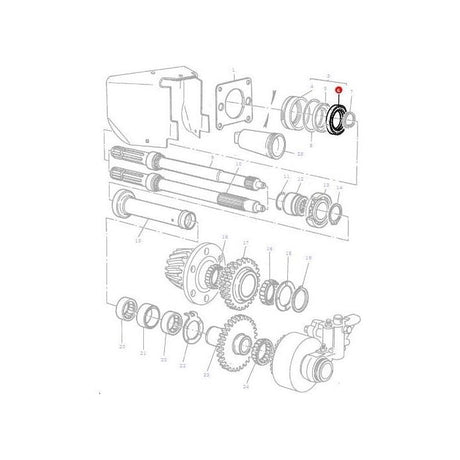

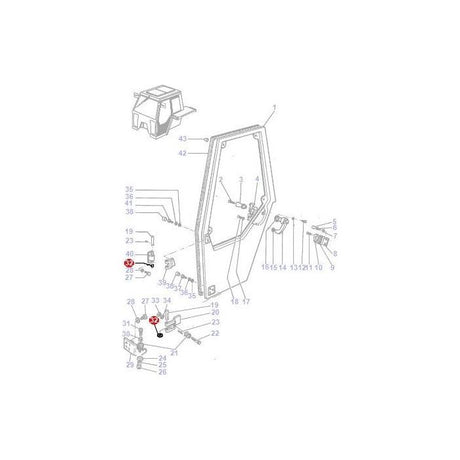

Seal and Hose Checks: Inspect hydraulic seals, hoses, and fittings for leaks, wear, or damage. Replace worn seals promptly to prevent fluid leaks and system inefficiencies.

-

Component Lubrication: Grease hydraulic fittings and pivot points regularly to reduce friction and wear, ensuring smooth operation and extending component lifespan.

-

Pressure and Temperature Monitoring: Periodically check hydraulic system pressure and fluid temperatures. Abnormal readings may indicate underlying issues requiring attention.

Thorough inspections and proactive maintenance mitigate risks and ensure reliable hydraulic system performance.

3. Troubleshooting and Repair Tips:

Equip yourself with troubleshooting skills to address common hydraulic system issues:

-

Identifying Leaks: Trace and diagnose hydraulic fluid leaks. Inspect fittings, seals, and hoses for signs of wear or damage. Repair leaks promptly to prevent fluid loss and maintain system integrity.

-

Air in the System: Bleed the hydraulic system to remove trapped air after fluid changes or repairs. Air pockets can affect hydraulic system performance and responsiveness.

-

Performance Testing: Conduct performance tests to evaluate hydraulic system functionality. Verify smooth operation of hydraulic functions and address any anomalies promptly.

Prompt troubleshooting and repairs minimize downtime and optimize Massey Ferguson 3050 tractor performance.

4. Preventive Maintenance Practices:

Implement proactive measures to extend hydraulic system lifespan:

-

Scheduled Maintenance: Follow manufacturer-recommended maintenance schedules for hydraulic system components. Adhere to service intervals for fluid changes, filter replacements, and component inspections.

-

Operator Training: Educate operators on proper hydraulic system operation and maintenance practices. Promote awareness of potential issues and proactive maintenance routines.

Preventive maintenance practices enhance reliability, minimize repair costs, and maximize Massey Ferguson 3050 tractor uptime.

5. Quality Parts and Support:

Accessing reliable parts and support ensures optimal hydraulic system performance:

-

OEM vs. Aftermarket: Consider using OEM parts for guaranteed compatibility and performance. Ensure parts sourced from reputable suppliers like Farmingparts.com.

-

Technical Support: Seek assistance from qualified technicians or support personnel for complex hydraulic system issues or troubleshooting.

Utilizing quality parts and support enhances confidence in hydraulic system reliability and performance.

Effective maintenance of the Massey Ferguson 3050 hydraulic system is critical for achieving long-term reliability and performance in agricultural operations. By implementing regular fluid checks, thorough inspections, proactive troubleshooting, and accessing quality parts and support, farmers can optimize their tractor's hydraulic system efficiency and ensure consistent productivity on the field.

Ready to enhance your Massey Ferguson 3050 hydraulic system maintenance? Explore Farmingparts.com for a comprehensive range of hydraulic fluids, filters, parts, and maintenance products designed to maximize your tractor's performance and longevity.